Scheduling and Sizing of Campus Microgrid Considering Demand Response and Economic Analysis

Abstract

:1. Introduction

2. Literature Review

3. Methodology

3.1. Proposed Conceptual Framework

3.2. Problem Methodology

3.3. Objective Function

3.4. Load Balancing Equality Constraint

3.5. Energy Storage System Constraints

3.6. Optimal Sizing of BESS

3.7. DG and Grid Constraints

3.8. Energy Participation between Grid and Prosumer

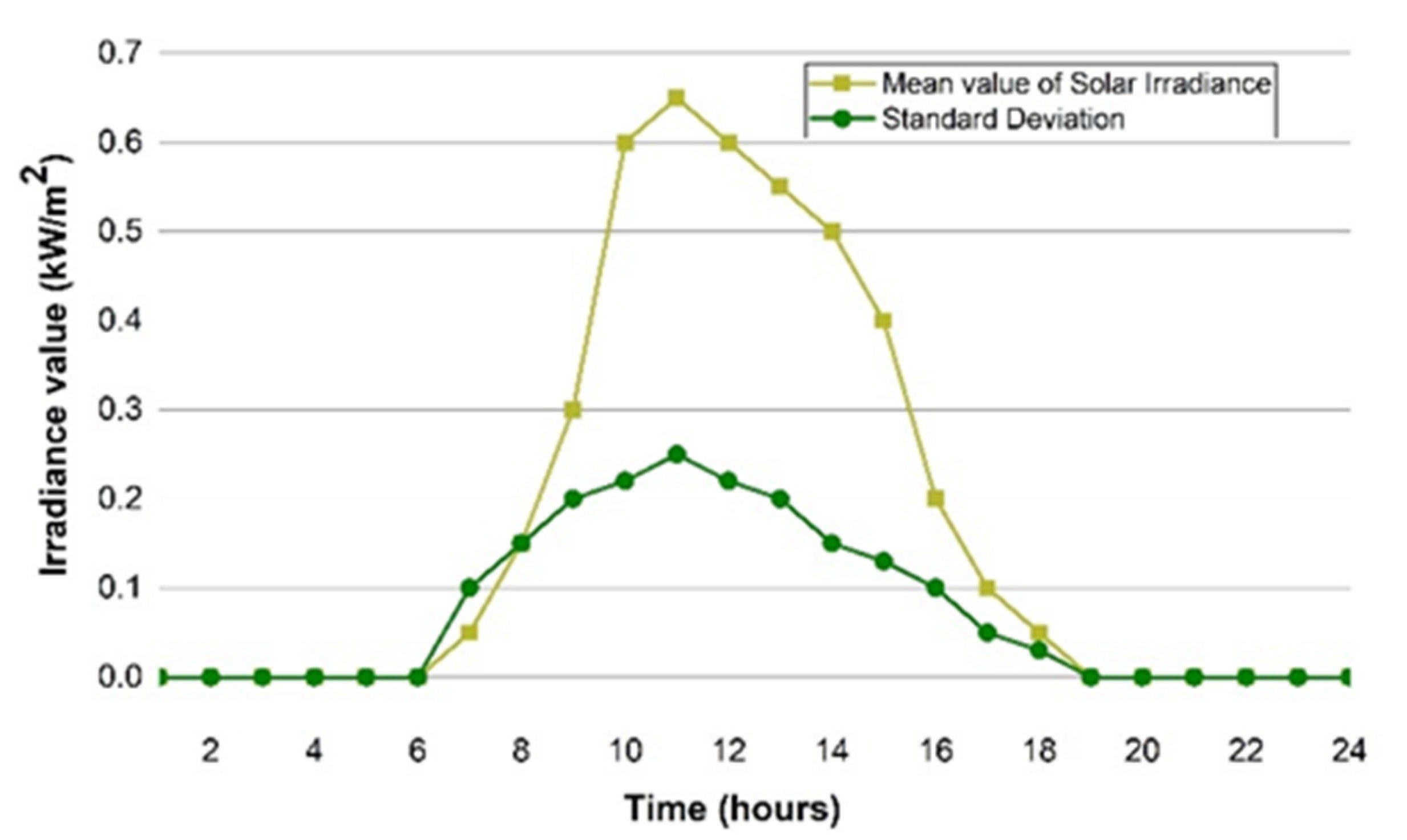

3.9. Stochastic Modelling of Solar PV

3.10. Energy Participation between Grid and Wind Turbine

3.11. Levelized Cost of Energy (LCOE)

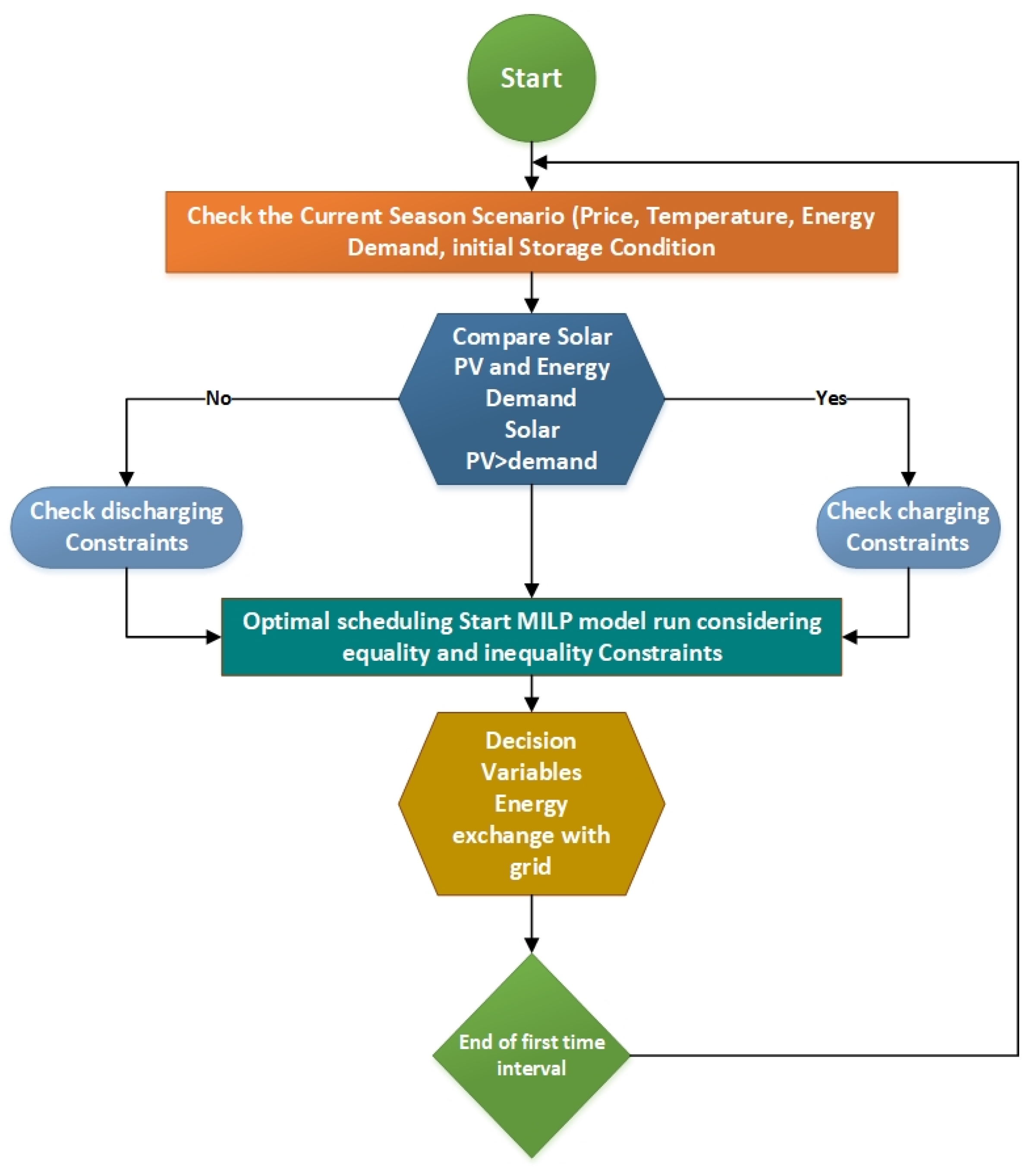

3.12. Solution Methodology

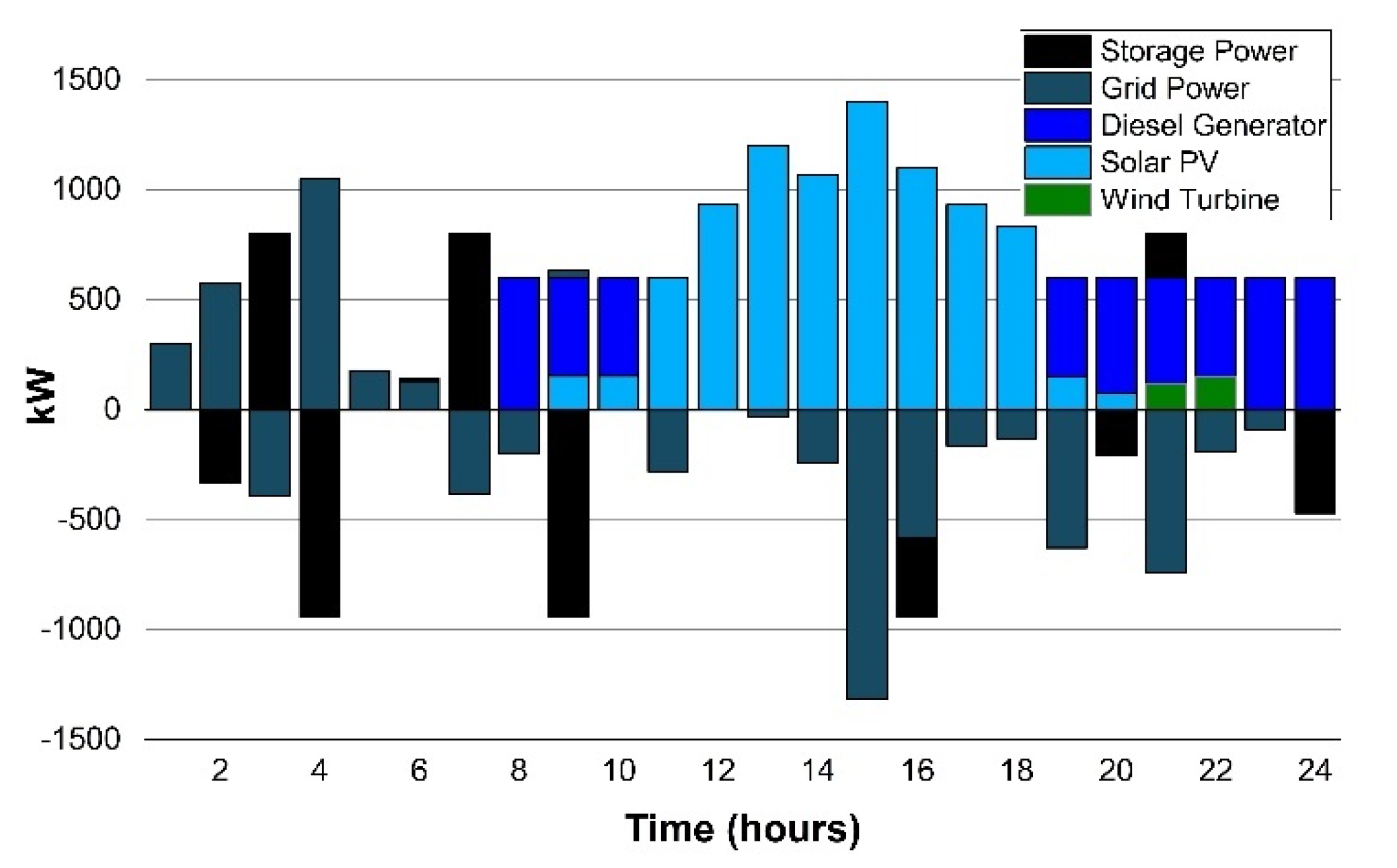

4. Results and Discussion

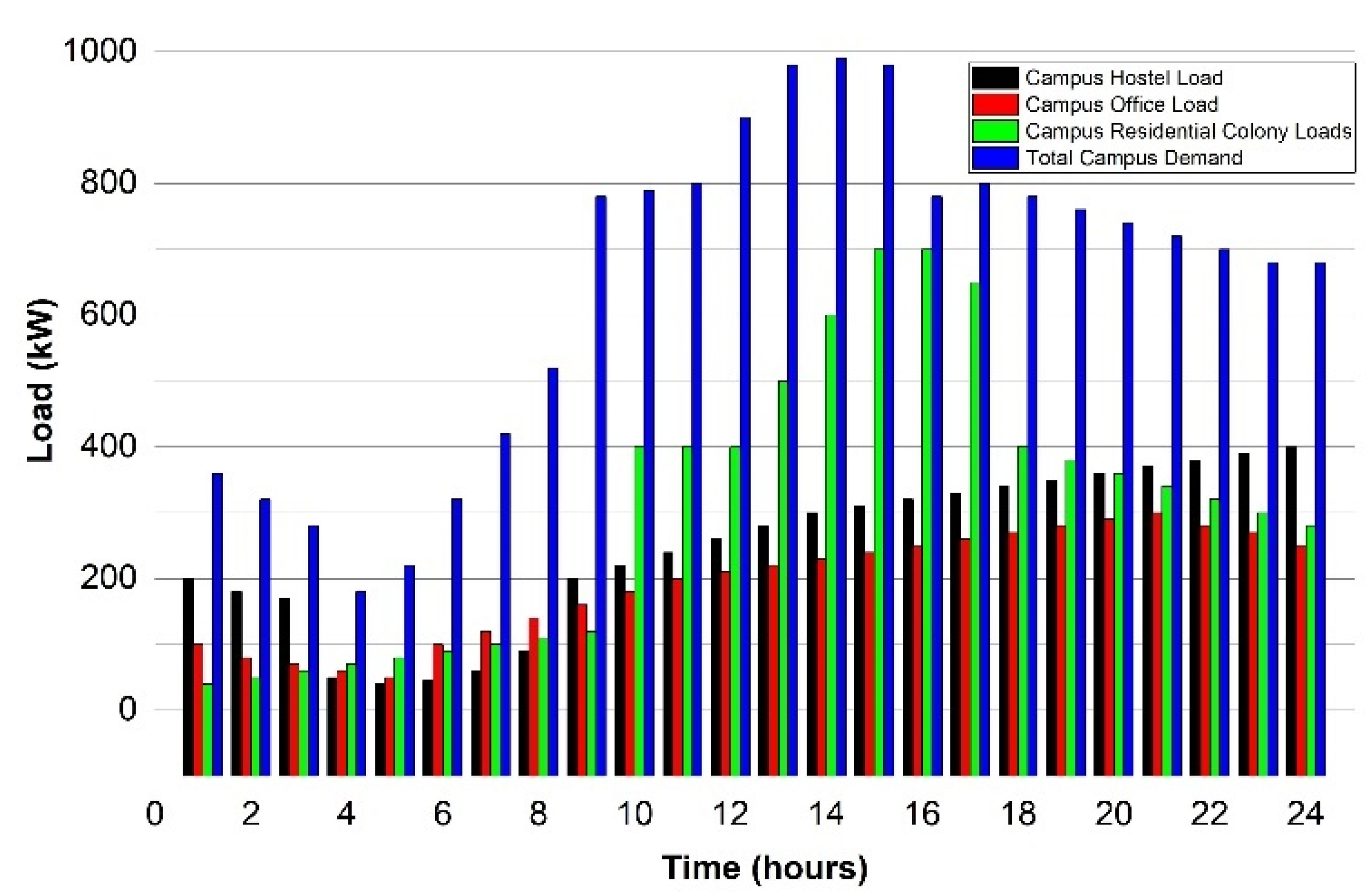

4.1. Case Study

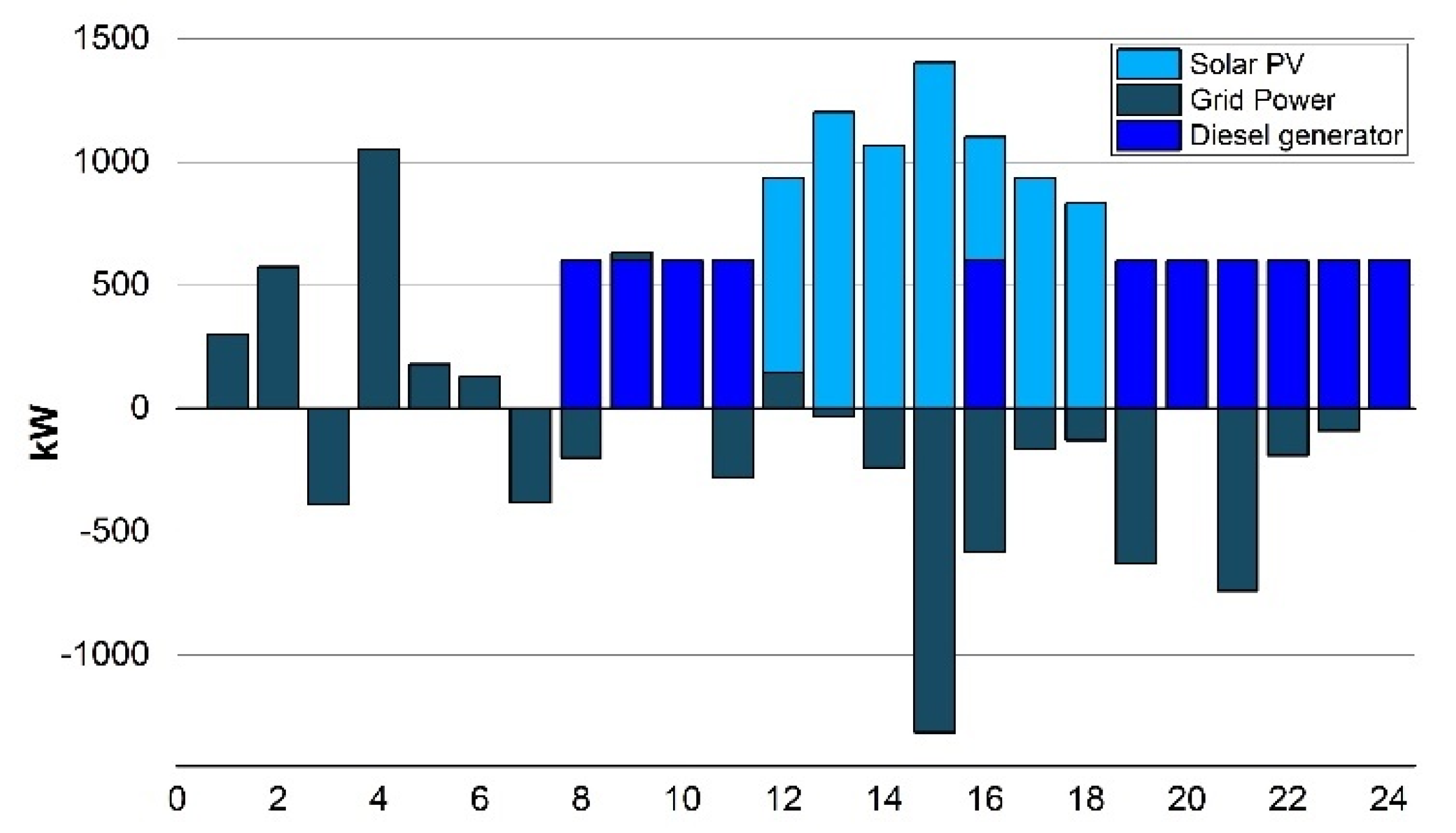

4.2. Multiple Case Scenarios

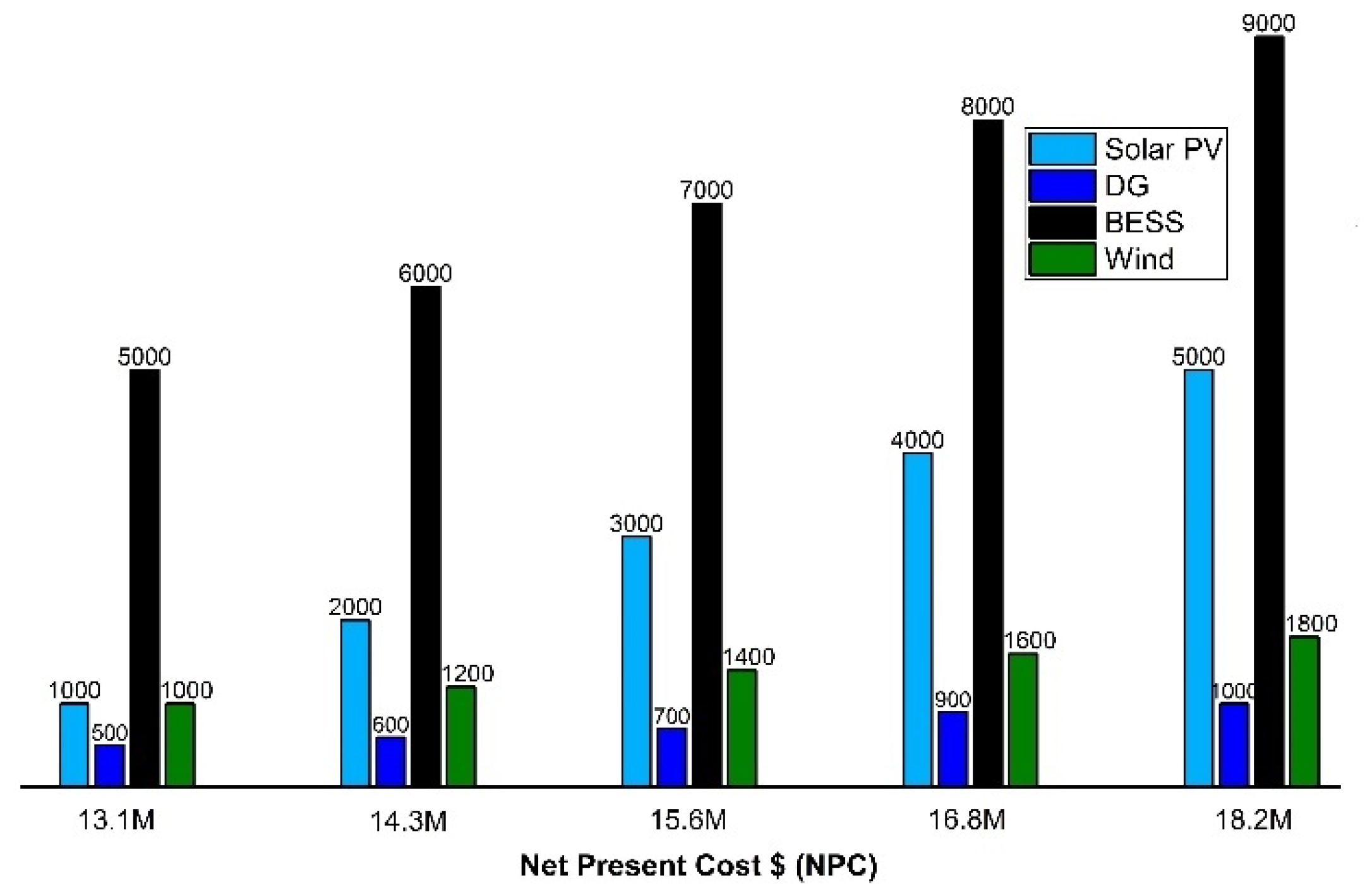

4.3. Sizing and Carbon Emissions Effects on Energy Cost

4.4. Economic Effects on Optimal BESS Sizing

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature and Acronym

| A. Acronyms | |

| BSOC | Battery state of charge |

| BESS | Battery energy storage system |

| DERs | Distributed energy resources |

| DG | Distributed generator |

| DSM | Demand-side management |

| EV | Electric vehicle |

| FIT | Feed-in-tariffs |

| TOU | Time of use |

| MILP | Mixed integer linear programming |

| GHG | Greenhouse gas |

| LP | Linear programming |

| RERs | Renewable energy resources |

| PV | Photovoltaic |

| B. Constants and Variables | |

| BSOCt | The starting value of BSOC at time 0 (%) |

| BSOCt | BSOC value at time interval t |

| BSOCmax | Maximum BSOC level (%) |

| BSOCmin | Minimum BSOC level (%) |

| Cost of diesel generator ($) | |

| Cost of storage degradation ($) | |

| Net cost of energy ($) | |

| Net cost of wind energy ($) | |

| Rated capacity of energy storage (kWh) | |

| J | Overall operations cost |

| µG | Microgrid |

| Solar PV output power (kW) | |

| Net energy exchange with the grid | |

| The output power of the battery (kW) | |

| Charging power of the battery (kW) | |

| Discharging power of storage system (kW) | |

| Storage gradient power (kW) | |

| The output power of diesel generator | |

| Grid power (kW) | |

| Load demand of prosumer (kW) | |

| Maximum power exchange limit of utility grid (kW) | |

| Minimum power exchange limit of utility grid (kW) | |

| Diesel generator rated capacity | |

| µ | Mean of solar irradiance |

| Storage charging integers/storage discharging integers | |

| Electricity rate ($/kWh) | |

| Standard deviation of the solar irradiance | |

| Diesel generator fuel curve intercept | |

| The efficiency of solar panel | |

| Area of a solar panel | |

| Diesel generator fuel curve slope | |

References

- Hirsch, A.; Parag, Y.; Guerrero, J. Microgrids: A review of technologies, key drivers, and outstanding issues. Renew. Sustain. Energy Rev. 2018, 90, 402–411. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Z.; Li, G.; Zhao, D.; Member, S. Optimal Scheduling of an Isolated Microgrid with Battery Storage Considering Load and Renewable Generation Uncertainties. IEEE Trans. Ind. Electron. 2019, 66, 1565–1575. [Google Scholar] [CrossRef]

- Lu, R.; Hong, S.H.; Zhang, X. A Dynamic pricing demand response algorithm for smart grid: Reinforcement learning approach. Appl. Energy 2018, 220, 220–230. [Google Scholar] [CrossRef]

- Jahangiri, M.; Mostafaeipour, A.; Rahman Habib, H.U.; Saghaei, H.; Waqar, A. Effect of Emission Penalty and Annual Interest Rate on Cogeneration of Electricity, Heat, and Hydrogen in Karachi: 3E Assessment and Sensitivity Analysis. J. Eng. 2021, 2021, 6679358. [Google Scholar] [CrossRef]

- Iqbal, M.M.; Sajjad, I.A.; Nadeem Khan, M.F.; Liaqat, R.; Shah, M.A.; Muqeet, H.A. Energy Management in Smart Homes with PV Generation, Energy Storage and Home to Grid Energy Exchange. In Proceedings of the 2019 International Conference on Electrical, Communication, and Computer Engineering (ICECCE), Swat, Pakistan, 24–25 July 2019; pp. 1–7. [Google Scholar] [CrossRef]

- El-Hendawi, M.; Gabbar, H.A.; El-Saady, G.; Ibrahim, E.N.A. Control and EMS of a grid-connected microgrid with economical analysis. Energies 2018, 11, 129. [Google Scholar] [CrossRef]

- Muqeet, H.A.U.; Ahmad, A. Optimal scheduling for campus prosumer microgrid considering price based demand response. IEEE Access 2020, 8, 71378–71394. [Google Scholar] [CrossRef]

- Abd, H.; Ahmad, A.; Sajjad, I.A.; Abrar, M. Optimal Operation of the Campus Microgrid Considering the Resource Uncertainty and Demand Response Schemes. Math. Probl. Eng. 2021, 2021, 5569701. [Google Scholar]

- Jahangiri, M.; Nematollahi, O.; Haghani, A.; Raiesi, H.A.; Alidadi Shamsabadi, A. An optimization of energy cost of clean hybrid solar-wind power plants in Iran. Int. J. Green Energy 2019, 16, 1422–1435. [Google Scholar] [CrossRef]

- Iqbal, M.M.; Waseem, M.; Manan, A.; Liaqat, R.; Muqeet, A.; Wasaya, A. IoT-Enabled Smart Home Energy Management Strategy for DR Actions in Smart Grid Paradigm. In Proceedings of the 2021 International Bhurban Conference on Applied Sciences and Technologies (IBCAST), Islamabad, Pakistan, 12–16 January 2021; pp. 352–357. [Google Scholar] [CrossRef]

- Shahab, M.; Wang, S.; Abd Ul Muqeet, H. Advanced Optimal Design of the IoT Based University Campus Microgrid Considering Environmental Concerns and Demand Response. In Proceedings of the 2021 6th International Conference on Power and Renewable Energy (ICPRE), Shanghai, China, 17–20 September 2021; pp. 798–802. [Google Scholar] [CrossRef]

- Kumar Nunna, H.S.V.S.; Amanbek, Y.; Satuyeva, B.; Doolla, S. A Decentralized Transactive Energy Trading Framework for Prosumers in a Microgrid Cluster. In Proceedings of the 2019 IEEE PES GTD Grand International Conference and Exposition Asia (GTD Asia), Bangkok, Thailand, 19–23 March 2019; pp. 824–830. [Google Scholar] [CrossRef]

- Uddin, M.; Romlie, M.F.; Abdullah, M.F.; Tan, C.K.; Shafiullah, G.M.; Bakar, A.H.A. A novel peak shaving algorithm for islanded microgrid using battery energy storage system. Energy 2020, 196, 117084. [Google Scholar] [CrossRef]

- Javed, H.; Irfan, M.; Shehzad, M.; Abdul Muqeet, H.; Akhter, J.; Dagar, V.; Guerrero, J.M. Recent Trends, Challenges, and Future Aspects of P2P Energy Trading Platforms in Electrical-Based Networks Considering Blockchain Technology: A Roadmap Toward Environmental Sustainability. Front. Energy Res. 2022, 10, 134. [Google Scholar] [CrossRef]

- Mehmood, M.Y.; Oad, A.; Abrar, M.; Munir, H.M.; Hasan, S.F.; Muqeet, H.A.U.; Golilarz, N.A. Edge Computing for IoT-Enabled Smart Grid. Secur. Commun. Netw. 2021, 2021, 5524025. [Google Scholar] [CrossRef]

- Ali, A.; Shakoor, R.; Raheem, A.; Muqeet, H.A.; Awais, Q.; Khan, A.A. Latest Energy Storage Trends in Multi Energy Standalone Electric Vehicle Charging Stations: A Comprehensive Study. Energies 2022, 15, 4727. [Google Scholar] [CrossRef]

- Gulzar, M.M.; Iqbal, M.; Shahzad, S.; Muqeet, H.A.; Shahzad, M.; Hussain, M.M. Load Frequency Control (LFC) Strategies in Renewable Energy Based Hybrid Power Systems: A Review. Energies 2022, 15, 3488. [Google Scholar] [CrossRef]

- Kristiawan, R.B.; Widiastuti, I.; Suharno, S. Technical and economical feasibility analysis of photovoltaic power installation on a university campus in Indonesia. MATEC Web Conf. 2018, 197, 08012. [Google Scholar] [CrossRef]

- Khan, M.M.; Shafi, M.A.; Akram, B.; Tariq, M.U.; Sarmad, R.; Muqeet, H.A.; Soucase, B.M. Financial Analysis of PV-Wind Cogeneration for a Remote Village in Gwadar-Pakistan. South. J. Res. 2022, 2, 145–152. [Google Scholar]

- Silva, V.A.; Aoki, A.R.; Lambert-Torres, G. Optimal Day-Ahead Scheduling of Microgrids with Battery Energy Storage System. Energies 2020, 13, 5188. [Google Scholar] [CrossRef]

- Waqar, A.; Tanveer, M.S.; Ahmad, J.; Aamir, M.; Yaqoob, M.; Anwar, F. Multi-objective analysis of a CHP plant integrated microgrid in Pakistan. Energies 2017, 10, 1625. [Google Scholar] [CrossRef]

- Rehman, S.U.; Rehman, S.; Shoaib, M.; Siddiqui, I.A. Feasibility Study of a Grid-Tied Photovoltaic System for Household in Pakistan: Considering an Unreliable Electric Grid. Environ. Prog. Sustain. Energy 2019, 38, e13031. [Google Scholar] [CrossRef]

- Gao, H.C.; Choi, J.H.; Yun, S.Y.; Lee, H.J.; Ahn, S.J. Optimal scheduling and real-time control schemes of battery energy storage system for microgrids considering contract demand and forecast uncertainty. Energies 2018, 11, 1371. [Google Scholar] [CrossRef]

- Ahmad, F.; Alam, M.S. Optimal Sizing and Analysis of Solar PV, Wind, and Energy Storage Hybrid System for Campus Microgrid. Smart Sci. 2018, 6, 150–157. [Google Scholar] [CrossRef]

- Zhang, X.; Grijalva, S. Smart Energy Campus: A Smart Grid Testbed for Advanced Modeling, Simulation, and Decision-Making. In Proceedings of the Tenth Carnegie Mellon Conference on the Electricity Industry, Pittsburgh, PA, USA, 30 March–1 April 2015; p. 1. [Google Scholar]

- De Simón-Martín, M.; Bracco, S.; Rossi, M.; Delfino, F.; González-Martínez, A.; Blanes-Peiró, J.J. A flexible test-bed pilot facility for the analysis and simulation of Smart Microgrids. In Proceedings of the 2019 IEEE International Conference on Environment and Electrical Engineering and 2019 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Genova, Italy, 11–14 June 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Javed, H.; Muqeet, H.A.; Shehzad, M.; Jamil, M.; Khan, A.A.; Guerrero, J.M. Optimal energy management of a campus microgrid considering financial and economic analysis with demand response strategies. Energies 2021, 14, 8501. [Google Scholar] [CrossRef]

- Nasir, M.; Khan, H.A.; Khan, I.; Hassan, N.U.; Zaffar, N.A.; Mehmood, A.; Sauter, T.; Muyeen, S.M. Grid load reduction through optimized PV power utilization in intermittent grids using a low-cost hardware platform. Energies 2019, 12, 1764. [Google Scholar] [CrossRef]

- Muqeet, H.A.; Sajjad, I.A.; Ahmad, A.; Iqbal, M.M.; Ali, S.; Guerrero, J.M. Optimal Operation of Energy Storage System for a Prosumer Microgrid Considering Economical and Environmental Effects. In Proceedings of the 2019 International Symposium on Recent Advances in Electrical Engineering (RAEE), Islamabad, Pakistan, 28–29 August 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Huo, C. A Microgrid Design Case Study: Synchrophasor Placement and Development of a Protection Laboratory for the Oregon State University-Corvallis Campus. Oregon State Univ. 2015, pp. 1–103. Available online: http://ir.library.oregonstate.edu/xmlui/handle/1957/56132 (accessed on 28 May 2022).

- Khan, K.R.; Siddiqui, M.S.; Saawy, Y.A.; Islam, N.; Rahman, A. Condition Monitoring of a Campus Microgrid Elements using Smart Sensors. Procedia Comput. Sci. 2019, 163, 109–116. [Google Scholar] [CrossRef]

- Gonzalez, R.M.; Van Goch, T.A.J.; Aslam, M.F.; Blanch, A.; Ribeiro, P.F. Microgrid design considerations for a smart-energy university campus. In Proceedings of the IEEE PES Innovative Smart Grid Technologies, Europe, Istanbul, Turkey, 12–15 October 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Kim, B. Implementation and optimal operation of campus microgrid-ems system considering multi-mg power trading. In Proceedings of the 25th International Conference and Exhibition on Electricity Distribution Cired 2019, Madrid, Spain, 3–6 June 2019; pp. 3–6. [Google Scholar]

- Brignone, M.; Delfino, F.; Fichera, M.; Procopio, R.; Barillari, L.; Nilberto, A. Optimal thermal power production by means of an equivalent electric circuit for a thermal network: The Savona Campus Smart Polygeneration Microgrid case. In Proceedings of the 2016 7th International Conference on Information, Intelligence, Systems & Applications (IISA), Chalkidiki, Greece, 13–15 July 2016. [Google Scholar] [CrossRef]

- Hao, S.; Coe, S. Scheduling of site battery energy storage for demand response capacity. In Proceedings of the 2015 Seventh Annual IEEE Green Technologies Conference, Washington, DC, USA, 15–17 April 2015; pp. 169–175. [Google Scholar] [CrossRef]

- Balouch, S.; Abrar, M.; Abdul Muqeet, H.; Shahzad, M.; Jamil, H.; Hamdi, M.; Malik, A.S.; Hamam, H. Optimal Scheduling of Demand Side Load Management of Smart Grid Considering Energy Efficiency. Front. Energy Res. 2022, 10, 861571. [Google Scholar] [CrossRef]

- Muqeet, H.A.; Munir, H.M.; Javed, H.; Shahzad, M.; Jamil, M.; Guerrero, J.M. An energy management system of campus microgrids: State-of-the-art and future challenges. Energies 2021, 14, 6525. [Google Scholar] [CrossRef]

- Javed, H.; Muqeet, H.A. Design, Model & Planning of Prosumer Microgrid for MNSUET Multan Campus. Sir Syed Univ. Res. J. Eng. Technol. 2021, 11, 1–7. [Google Scholar]

- Shahzad Pansota, M.; Javed, H.; Muqeet, H.A.; Khan, H.A.; Ahmed, N.; Usama Nadeem, M.; Faheem Ahmed, S.U.; Sarfraz, A. An Optimal Scheduling and Planning of Campus Microgrid Based on Demand Response and Battery Lifetime. Pak. J. Eng. Technol. 2021, 4, 8–17. [Google Scholar]

- Muqeet, H.A.; Ahmad, A.; Sajjad, I.A.; Liaqat, R.; Raza, A.; Iqbal, M.M. Benefits of Distributed Energy and Storage System in Prosumer Based Electricity Market. In Proceedings of the 2019 IEEE International Conference on Environment and Electrical Engineering and 2019 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Genova, Italy, 11–14 June 2019; pp. 3–8. [Google Scholar] [CrossRef]

- Nasir, T.; Raza, S.; Abrar, M.; Ul Muqeet, H.A.; Jamil, H.; Qayyum, F.; Cheikhrouhou, O.; Alassery, F.; Hamam, H. Optimal scheduling of campus microgrid considering the electric vehicle integration in smart grid. Sensors 2021, 21, 7133. [Google Scholar] [CrossRef]

- Nasir, T.; Bukhari, S.S.H.; Raza, S.; Munir, H.M.; Abrar, M.; Ul Muqeet, H.A.; Bhatti, K.L.; Ro, J.-S.; Masroor, R. Recent Challenges and Methodologies in Smart Grid Demand Side Management: State-of-the-Art Literature Review. Math. Probl. Eng. 2021, 2021, 5821301. [Google Scholar] [CrossRef]

- Sekhar, D.C.; Rao, P.V.V.R.; Kiranmayi, R. Conceptual Review on Demand Side Management, Optimization Techniques for the Improvement of Power Quality in Smart Grids. In Proceedings of the 2022 Second International Conference on Artificial Intelligence and Smart Energy (ICAIS), Coimbatore, India, 23–25 February 2022; pp. 1640–1647. [Google Scholar]

- Muqeet, H.A.; Javed, H.; Akhter, M.N.; Shahzad, M.; Munir, H.M.; Nadeem, M.U.; Sabir, S.; Bukhari, H.; Huba, M. Sustainable Solutions for Advanced Energy Management System of Campus Microgrids: Model Opportunities and Future Challenges. Sensors 2022, 22, 2345. [Google Scholar] [CrossRef]

- Hafiz Abdul Muqeet, A.A. Optimal Day-Ahead Operation of Microgrid Considering Demand Response and Battery Strategies for Prosumer Community. Tech. J. UET Taxila 2020, 25, 1–13. [Google Scholar]

- Das, B.K.; Zaman, F. Performance analysis of a PV/Diesel hybrid system for a remote area in Bangladesh: Effects of dispatch strategies, batteries, and generator selection. Energy 2019, 169, 263–276. [Google Scholar] [CrossRef]

- Zhang, M. Sizing and Siting of Distributed Generators and Energy Storage in a Microgrid Considering Plug-in Electric Vehicles. Energies 2019, 12, 2293. [Google Scholar] [CrossRef]

- Shimotakahara, K.; Elsayed, M.; Hinzer, K.; Erol-Kantarci, M. High-Reliability Multi-Agent Q-Learning-Based Scheduling for D2D Microgrid Communications. IEEE Access 2019, 7, 74412–74421. [Google Scholar] [CrossRef]

- Raza, A.; Malik, T.N. Energy management in commercial building microgrids. J. Renew. Sustain. Energy 2019, 11, 015502. [Google Scholar] [CrossRef]

- Ayta, S.; Electronic, K.; Electric, F.E. Quality Lignite Coal Detection with Discrete Wavelet Transform, Discrete Fourier Transform, and ANN based on k-means Clustering Method. In Proceedings of the 2018 6th International Symposium on Digital Forensic and Security (ISDFS), Antalya, Turkey, 22–25 March 2018; pp. 1–6. [Google Scholar]

- Aslam Chaudhry, M. Extended incomplete gamma functions with applications. J. Math. Anal. Appl. 2001, 274, 725–745. [Google Scholar] [CrossRef]

- Tahir, Z.R.; Asim, M. Surface measured solar radiation data and solar energy resource assessment of Pakistan: A review. Renew. Sustain. Energy Rev. 2018, 81, 2839–2861. [Google Scholar] [CrossRef]

- Lai, C.S.; McCulloch, M.D. Levelized cost of electricity for solar photovoltaic and electrical energy storage. Appl. Energy 2017, 190, 191–203. [Google Scholar] [CrossRef]

- Pickering, B.; Ikeda, S.; Choudhary, R.; Ooka, R. Comparison of Metaheuristic and Linear Programming Models for the Purpose of Optimising Building Energy Supply Operation Schedule. In Proceedings of the CLIMA 2016: 12th REHVA World Congress, Aalborg, Denmark, 25 May 2016. [Google Scholar]

- Reporter, S. IBA University to Supply Solar Power to Sepco. Nov. 28, 2019. 2019. Available online: https://nation.com.pk/26-Jan-2019/iba-university-to-supply-solar-power-to-sepco (accessed on 28 May 2022).

- Iqbal, M.M.; Sajjad, I.A.; Amin, S.; Haroon, S.S.; Liaqat, R.; Khan, M.F.N.; Waseem, M.; Shah, M.A. Optimal scheduling of residential home appliances by considering energy storage and stochastically modelled photovoltaics in a grid exchange environment using hybrid grey wolf genetic algorithm optimizer. Appl. Sci. 2019, 9, 5226. [Google Scholar] [CrossRef]

- Vahedipour-Dahraie, M.; Rashidizadeh-Kermani, H.; Anvari-Moghaddam, A.; Guerrero, J.M. Stochastic Frequency-Security Constrained Scheduling of a Microgrid Considering Price-Driven Demand Response. In Proceedings of the 2018 International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM), Amalfi, Italy, 20–22 June 2018; pp. 716–721. [Google Scholar] [CrossRef]

- Azimian, M.; Amir, V.; Javadi, S. Economic and Environmental Policy Analysis for Emission-Neutral Multi-Carrier Microgrid Deployment. Appl. Energy 2020, 277, 115609. [Google Scholar] [CrossRef]

- Ul, S.; Hashmi, H.; Ulasyar, A.; Zad, H.S.; Khattak, A.; Imran, K. Optimal Day-Ahead Scheduling for Campus Microgrid by using MILP Approach. Pak. J. Eng. Technol. PakJET 2021, 4, 21–27. [Google Scholar]

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| 2000 kW | 800 kWh | ||

| 2000 kW | −1000 kW | ||

| 800 kW | −800 kW | ||

| 90% | 0.95 | ||

| 50% | Battery Lifetime (LTY) | 10 | |

| BESS Fixed-price | 70.875 | SOHM | 0.6 |

| Tariff Pricing | |

|---|---|

| Timing (Hours) | Unit Prices ($) |

| 12:00 a.m. to 7:00 p.m. | 0.10 |

| 7:00 p.m. to 11:00 p.m. | 0.138 |

| 11:00 p.m. to 12:00 a.m. | 0.10 |

| Cases | Only Grid | PV | ESS | DG | Wind | Energy Import by Grid (kWh /Day) | Electricity Generated from Prosumer (kWh /Day) | Grid Electricity Net Cost/Day ($) * | CC ** ($/ Day) | Electricity Net Cost without CC/Day ($) 1 | Electricity Net Cost CC/Day ($) | LCOE ($/kWh) | % Saving |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | (C = B − A) | |||||||||||

| (a) | ✓ | × | × | × | × | 141,72.5 | - | 1430.8 | - | 1430.8 | 1430.8 | 0.101 | - |

| (b) | ✓ | ✓ | × | × | × | 5548.8 | 8623.7 | 610.7 | 165 | 923.5 | 758.5 | 0.055 | 42.9 |

| (c) | ✓ | ✓ | ✓ | × | × | 5548.8 | 8623.7 | 711.5 | 165 | 899.9 | 734.9 | 0.056 | 41.2 |

| (d) | ✓ | ✓ | ✓ | ✓ | × | 4784.2 | 8623.7 | 768.2 | 155 | 835.5 | 680.6 | 0.058 | 37.4 |

| (e) | ✓ | ✓ | ✓ | ✓ | ✓ | 4643.2 | 8893.9 | 546.4 | 145 | 813.8 | 668.8 | 0.060 | 36.6 |

| Ref. | Year | Application | Technique | Remarks | Savings |

|---|---|---|---|---|---|

| [23] | 2018 | Campus µG | MILP | ESS Degradation cost, Peak demand | 5.32% |

| [57] | 2018 | Residential Level | MILP | Frequency regulation | 7% |

| [28] | 2019 | Residential µG | LP | Grid outage | 16% |

| [58] | 2020 | Campus µG | MILNP | Electrical peak mitigation | 23% |

| [59] | 2021 | Campus µG | MILP | ESS Degradation cost, Peak demand | 5.27% |

| Proposed Model | 2022 | Campus µG | MILP | Self-consumption, ESS Degradation, Demand response, Optimal sizing & Economic analysis | 36.3% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bin, L.; Shahzad, M.; Javed, H.; Muqeet, H.A.; Akhter, M.N.; Liaqat, R.; Hussain, M.M. Scheduling and Sizing of Campus Microgrid Considering Demand Response and Economic Analysis. Sensors 2022, 22, 6150. https://doi.org/10.3390/s22166150

Bin L, Shahzad M, Javed H, Muqeet HA, Akhter MN, Liaqat R, Hussain MM. Scheduling and Sizing of Campus Microgrid Considering Demand Response and Economic Analysis. Sensors. 2022; 22(16):6150. https://doi.org/10.3390/s22166150

Chicago/Turabian StyleBin, Li, Muhammad Shahzad, Haseeb Javed, Hafiz Abdul Muqeet, Muhammad Naveed Akhter, Rehan Liaqat, and Muhammad Majid Hussain. 2022. "Scheduling and Sizing of Campus Microgrid Considering Demand Response and Economic Analysis" Sensors 22, no. 16: 6150. https://doi.org/10.3390/s22166150

APA StyleBin, L., Shahzad, M., Javed, H., Muqeet, H. A., Akhter, M. N., Liaqat, R., & Hussain, M. M. (2022). Scheduling and Sizing of Campus Microgrid Considering Demand Response and Economic Analysis. Sensors, 22(16), 6150. https://doi.org/10.3390/s22166150